Investment casting is one of the complex casting processes. It can not only form the complex structure of parts, but also achieve high dimensional accuracy and surface quality. Investment casting can be used to produce almost all metal products to meet the needs of a wide range of end markets.

Investment casting is a metal forming process. Ceramic mold is formed by coating ceramic heat-resistant materials on the surface of wax mold. The formed ceramic mold is dried and melted to remove the wax mold and then form a mold shell. Then, the molten metal is poured into the ceramic mold shell, and the mold shell is removed after the metal is formed, so as to obtain the casting. Some investment castings need post processing after casting. Investment casting process is usually used to produce parts with complex shape and high dimensional accuracy and surface quality.

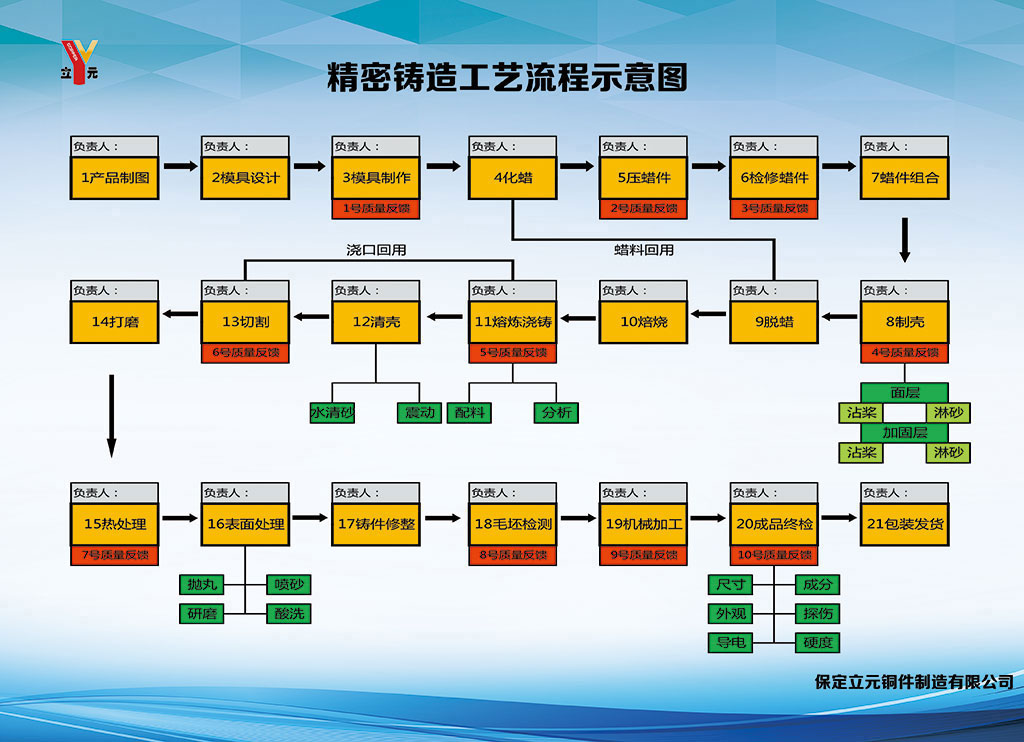

中文

中文 EN

EN